In today’s rapidly evolving industrial automation landscape, selecting durable hardware like Panel PCs, HMIs (Human-Machine Interfaces), or edge computing devices is critical. Among the most common specifications you’ll encounter is the IP65 rating. But what does this classification truly mean, and how does it impact your smart manufacturing or Industry 4.0 initiatives? This guide dives deep into IP standards, their applications, and how to choose the right solution for your environment.

Governed by the International Electrotechnical Commission (IEC 60529), the Ingress Protection (IP) rating system provides a universal framework to evaluate an enclosure’s ability to resist dust, water, and physical intrusion. Widely adopted in industrial IoT (IIoT), robotics, and process control, this standard ensures consistency across industries and geographies.

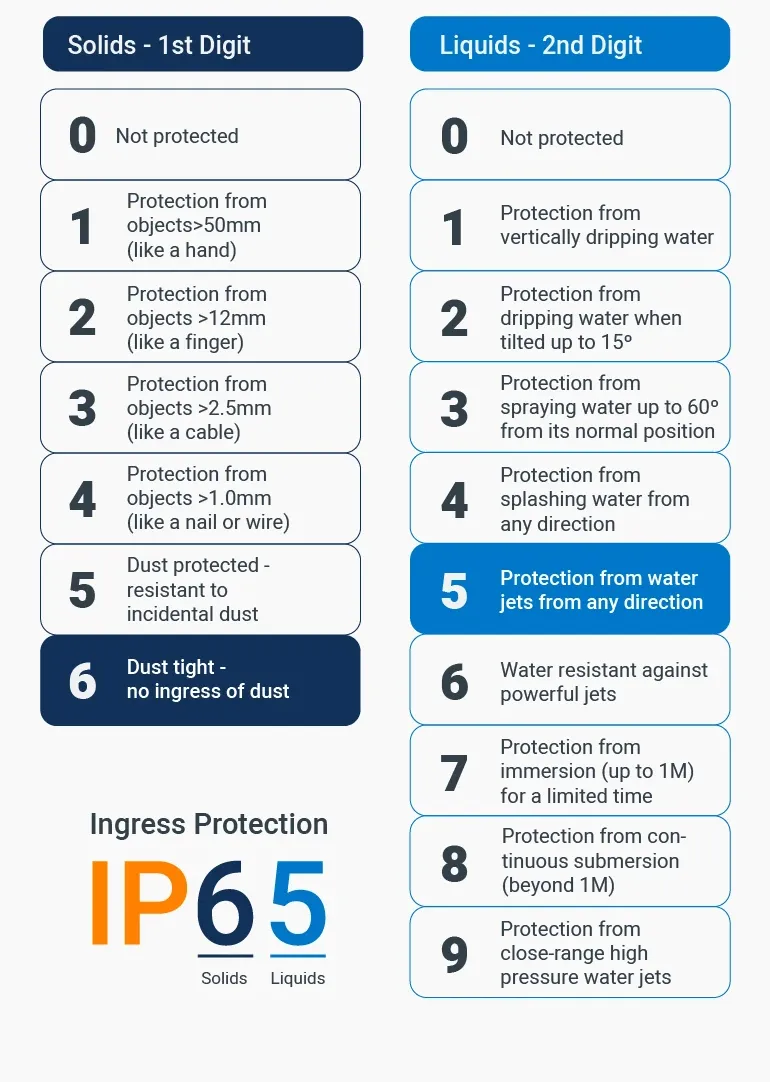

An IP code comprises two digits:

First digit (0–6): Protection against solid particles (e.g., tools, dust, fingers).

Second digit (0–9K): Protection against liquids (e.g., water sprays, submersion).

First Digit: “6” – Total Dust Ingress Prevention

A “6” represents the highest level of protection against solids. Devices rated “6” are dust-tight, tested under vacuum conditions with talcum powder for 8 hours. This is essential in industries like cement production, mining, or agriculture, where fine particulates can cripple sensitive electronics.

Second Digit: “5” – Resistance to Low-Pressure Water Jets

The “5” indicates protection against water jets (6.3mm nozzle) at 30 kPa pressure from any angle. While not waterproof, IP65 devices endure washdown procedures, outdoor humidity, or accidental spills—common in food processing, pharmaceutical cleanrooms, or beverage bottling lines.

IP65 Ratings:

From factory automation to smart cities, IP65-rated devices bridge the gap between standard office-grade hardware and ruggedized solutions.

Food & Beverage Industry

Resists grease, flour dust, and sanitizer sprays during CIP (Clean-in-Place) processes.

Deployed in packaging lines, mixer control stations, or cold storage monitoring.

Outdoor Digital Signage & Kiosks

Withstands rain, snow, and dust in retail hubs, public transit, or EV charging stations.

Sunlight-readable displays ensure visibility in direct UV exposure.

Automotive Manufacturing

Protects against coolant splashes, metal shavings, and oil mist on robotic assembly lines.

Agricultural Technology (AgTech)

Survives grain dust, fertilizer particulates, and humidity in smart greenhouses or livestock monitoring systems.

While IP65 is versatile, proper implementation ensures longevity. Consider these factors:

1. Partial vs. Full Enclosure Protection

Many Panel PCs only have an IP65-rated front bezel. Verify if the entire chassis meets the standard, especially for edge computing deployments in dusty environments.

2. Material Compatibility

Stainless steel or polycarbonate housings resist corrosion in chemical processing or wastewater treatment plants.

3. Temperature & Vibration Resistance

Pair IP65 with wide-temperature operation (-30°C to 70°C) for oil & gas or renewable energy applications.

Anti-vibration mounts prevent damage in material handling or construction machinery.

4. Certification Authenticity

Ensure third-party IEC 60529 testing—some manufacturers self-certify without rigorous validation.

While IP65 covers most scenarios, certain environments demand stricter protection:

IP67/IP68: For submersion-prone areas like aquaculture sensors or underwater robotics.

IP69K: Mandatory in pharmaceutical sterilization or dairy pasteurization lines using 80°C high-pressure jets.

NEMA 4X: Combines IP66 with corrosion resistance for marine or coastal installations.

Overlooking Installation Requirements

Even IP65 devices fail if cable glands or gaskets are improperly sealed. Follow OEM guidelines for conduit connections or panel mounting.

Ignoring Complementary Standards

Pair IP ratings with ATEX for explosive atmospheres or MIL-STD-810G for shock/vibration in defense or aerospace.

Assuming “Waterproof” Capabilities

IP65 ≠ waterproof. For prolonged water exposure, use IP67 or submersible enclosures.

As industrial IoT expands, IP65-rated edge devices and gateways are becoming the backbone of predictive maintenance and real-time analytics. These systems collect data from PLC controllers, sensors, and vision systems in harsh environments, enabling:

Condition monitoring of machinery in dusty factories.

Remote management of outdoor solar farms or wind turbines.

Hygienic touchscreens for pharmaceutical track-and-trace compliance.

With growing emphasis on circular economy practices, manufacturers are designing IP65 devices with:

Modular components for easy repair/reuse in recycling facilities.

Energy-efficient displays to reduce power consumption in smart grids.

Eco-friendly materials aligned with ISO 14001 environmental standards.

IP65 remains a gold standard for industrial automation, offering robust defense against dust and water at a reasonable cost. However, always align your choice with risk assessments and total cost of ownership (TCO) analyses. For instance:

A warehousing robot may thrive with IP65, while a deep-sea sensor needs IP68.

A brewery’s fermentation control panel could opt for IP65, but its bottling line may require IP69K.

By integrating IP-rated hardware with predictive analytics and IIoT platforms, businesses can future-proof operations while minimizing downtime.

Explore our IP65-rated Industrial Panel PCs and HMIs, engineered for harsh environments with features like capacitive multi-touch, fanless cooling, and sunlight-readable displays. Whether you’re automating a textile factory or deploying smart city infrastructure, our solutions combine durability with scalable computing power to drive your digital transformation forward.

Contact our technical team today to discuss your project’s unique needs—from dusty mining sites to high-humidity food plants, we’ll help you navigate IP standards and beyond.

Click to confirm

Cancel