CNC numerical control is very common in the current manufacturing industry. It is not a rare thing to have CNC numerical control technology. The difficulty lies in how to improve CNC efficiency, stability and output. These devices, crucial for modern factories, offer precision, reliability, and durability. If you are not satisfied with the efficiency of the existing CNC machines, you might as well try reading this article. This article will tell you how to improve the accuracy and efficiency of CNC numerical control through industrial mini PCs. In this article, we explore the role of industrial PCs in automating CNC systems, focusing on the benefits of fanless mini PCs, industrial computers, and embedded computers. We will also provide insights into their integration into industrial automation processes.

An industrial PC is a rugged, reliable computer designed for use in harsh industrial environments. These systems are engineered to withstand extreme conditions such as high temperatures, vibration, and dust. They differ from commercial computers in their durability and ability to function without failure in demanding settings. Industrial mini PCs, in particular, are compact versions of these systems, designed for applications where space is limited. These machines combine the power of a full-fledged industrial PC with a small form factor.

CNC systems are pivotal in modern manufacturing processes. CNC machines use programmed commands to control tools and equipment with high precision, such as the movement of robotic arms and the filling of materials. But without the control of workers, we need a stable program to control everything. This requires reliable industrial computers for real-time data processing, system monitoring and control. Industrial PCs are used as the central processing unit in CNC machinery to handle various tasks, including:

1. Processing complex calculations for tool movements

2. Monitoring machine performance in real time

3. Interfacing with external devices and sensors

4. Storing large datasets for analysis and reporting

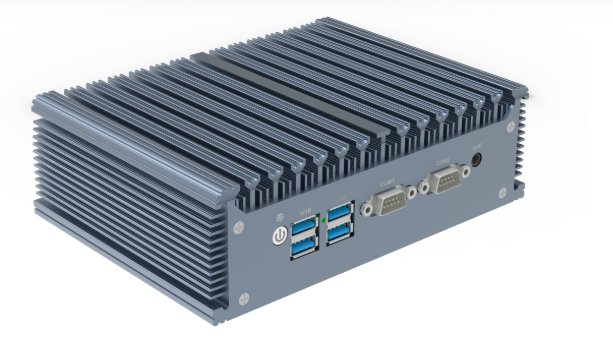

With the growing need for smaller yet more powerful systems, fanless mini PCs have become a top choice for CNC automation. Their compact design reduces space requirements, their fanless design keeps out dust and debris, and their aluminum housing increases heat dissipation, making them ideal for the factory floor.

One of the most significant trends in industrial computing is the adoption of fanless mini PCs. Unlike traditional PCs that rely on fans for cooling, fanless designs use heat sinks or advanced thermal management systems to dissipate heat. This eliminates the need for moving parts, which can wear out over time or get clogged with dust. The fanless mini PC is compact, making it easier to integrate into tight spaces on factory floors, and it offers enhanced durability, as there are fewer mechanical parts that could fail.

In CNC applications, fanless mini PCs play a crucial role by providing a stable and continuous operation, even under heavy workloads. Their passive cooling design also helps reduce noise levels, making the working environment more comfortable for operators.

There are several reasons why industrial mini PCs have become a preferred choice for CNC applications:

Space Efficiency: The compact size of industrial mini PCs means they take up less space on factory floors, which the size is one tenth of a traditional desktop computer

Durability: Designed to withstand extreme conditions, industrial mini PCs are more reliable in tough environments where traditional computers may fail. For example, the empty chassis of traditional computers will accumulate a lot of dust, which will cause the heat dissipation performance to decrease. However, the compact and fanless design of industrial mini computers can make you no longer worry about such problems. Their robust construction ensures longevity, even in high-vibration or high-temperature settings.

Low Power Consumption: Many industrial mini PCs use energy-efficient processors, contributing to lower operating costs and reducing the need for additional cooling systems.The power of traditional office computers is generally between 150-250W, and the power of high-performance gaming computers is generally between 500-800W. The power of ordinary industrial mini computers is between 15-30W (CPU is AMD Ryzen Embedded, etc.), and the power of medium-performance ones is between 30-60W, such as BVS's GW-B-PLUS mini industrial pc, which is used for industrial control, data processing and multi-tasking that require higher computing power. Therefore, in terms of power consumption, mini industrial PCs are almost one-tenth of traditional computers, which can save a lot of electricity costs for factories.

High Performance: Despite their small size, industrial mini PCs are equipped with powerful processors that can handle intensive workloads, making them perfect for CNC automation. It can even be combined with artificial intelligence to handle more complex tasks

While both industrial computers and embedded computers are used in automation applications, there are key differences:

· Industrial Computers are standalone systems designed for industrial environments. They typically include a full-sized motherboard, allowing for more upgrade options and versatility in terms of software and hardware configurations.

· Embedded Computers are smaller, more specialized systems that are integrated into larger machines or devices. They are typically used in applications where space is at a premium, and the computer needs to perform specific tasks (like controlling a CNC machine).

Both types of systems are critical for modern automation but serve different needs. Embedded computers are usually deployed in environments where minimal interaction with the system is required, while industrial computers are used where more complex and customizable computing power is needed.

The future of industrial PCs in CNC automation looks promising. As manufacturing processes become more complex, the demand for smaller, more powerful, and more reliable computing systems will continue to grow. Fanless mini pc will bring more efficient designs as hardware upgrades, providing more powerful processing power in a smaller form factor. Advances in IoT (Internet of Things) integration will also enable real-time data analysis and predictive maintenance, improving productivity and reducing downtime.

Moreover, the integration of artificial intelligence and machine learning into CNC systems will create a more intelligent automation environment. Embedded computers will play a significant role in this transformation, providing the computing power needed to run complex algorithms that enhance the capabilities of CNC machines.

|

Feature |

Industrial PC |

Embedded Computer |

|

Size |

Larger, often rack-mounted |

Compact, designed for integration |

|

Performance |

High processing power, versatile |

Task-specific, lower power |

|

Customization |

Highly customizable |

Limited customization options |

|

Durability |

Rugged, designed for harsh conditions |

Less rugged, designed for specific tasks |

|

Use Case |

Versatile, suitable for diverse applications |

Integrated into larger machinery or devices |

Looking for the perfect industrial PC to enhance your automation processes? The GW-B-PLUS offers high-performance computing in a compact form factor, perfect for a variety of industrial applications, including CNC systems. Featuring robust build quality, powerful processing capabilities, and flexible customization options, the GW-B-PLUS is your ideal solution for streamlining industrial automation.

Take advantage of our Christmas discount and get your GW-B-PLUS at an unbeatable price.

Visit our product page now to learn more and place your order

Click to confirm

Cancel