In demanding industrial settings like manufacturing facilities and heavy-duty vehicles, vibrations are a constant challenge. High-vibration environments can significantly impact the performance and lifespan of traditional computers, leading to potential downtimes and maintenance costs. To address these challenges, fanless industrial PCs are engineered to withstand mechanical stress while maintaining stable performance. This article explores how fanless industrial PCs can endure harsh conditions with the help of advanced components like shock-resistant mounts, solid-state drives (SSDs), and ruggedized casings. We’ll also look at some real-world examples of fanless PCs designed specifically for high-vibration environments.

In environments like factory floors, industrial vehicles, or mining sites, constant vibrations can damage sensitive internal components of traditional computers. Hard disk drives (HDDs) are particularly vulnerable, as their moving parts can easily be displaced, leading to data loss or even complete failure. The same goes for cooling fans, which can loosen over time, impacting the computer’s cooling capabilities and increasing the risk of overheating. By contrast, fanless industrial PCs use a combination of robust design and innovative technologies to avoid these issues, ensuring consistent operation and extended hardware life.

Fanless PCs are built with specialized components and construction techniques to help them function effectively under harsh conditions. Here are some ways fanless industrial PCs tackle the challenges of high-vibration environments:

Traditional hard drives with spinning disks are vulnerable to vibrations, but fanless industrial PCs commonly use solid-state drives (SSDs) instead. Unlike HDDs, SSDs have no moving parts, making them far more resilient to mechanical shocks and vibrations. For instance, the BV-Series from BVS IPC, known for its durability, includes SSDs as standard storage, making it suitable for rugged environments. SSDs not only enhance the reliability of these systems in high-vibration settings but also contribute to faster data access and lower power consumption, adding to their appeal in industrial applications.

To further protect sensitive components, fanless industrial PCs are often equipped with shock-resistant mounts. These mounts help absorb vibrations, minimizing the impact on critical hardware like the motherboard and SSD. Shock absorption technology, such as that found in BSI Fanless Micro PC models, allows these devices to operate in high-vibration areas without risking internal damage. By isolating components from external movement, shock-resistant mounts ensure that PC industrial fanless models can maintain performance and reduce the chances of system failure.

The external casing of a fanless industrial PC is crucial for its protection in industrial environments. Durable materials like aluminum or reinforced steel are often used for the chassis, providing both heat dissipation and protection against physical shocks. For instance, the BZ Series Fanless Embedded PC by BVS IPC features a rugged casing that’s not only vibration-resistant but also highly effective at dissipating heat, thus enhancing the computer's performance. This type of rugged fanless PC is ideal for installation on heavy-duty vehicles or equipment where physical stress is constant.

Fanless PCs are distinctly better suited to high-vibration environments compared to traditional desktop PCs, which rely heavily on cooling fans and HDDs. In a fanless mini PC design, passive cooling is achieved through heat sinks and the ruggedized casing itself, eliminating the need for fans. This means fewer parts are susceptible to wear and tear over time, enhancing reliability in harsh conditions. Moreover, fanless industrial mini PCs can be compact, which makes them easier to integrate into tight spaces where vibration and other mechanical stresses are common.

Many industries benefit from using fanless industrial PCs in high-vibration environments. Below are some common applications:

· Manufacturing: On the factory floor, machinery constantly generates vibrations that can destabilize ordinary PCs. Fanless embedded PCs are used to monitor and control machinery, providing reliable performance and low maintenance.

· Mining and Construction: Vehicles and equipment in mining and construction are often subjected to extreme vibrations. Rugged fanless PCs provide data collection and process control solutions in these environments, where consistent performance is crucial.

· Transportation: Public transportation systems and logistics vehicles use mini PC industrial fanless models to handle GPS, monitoring, and communication tasks. These PCs’ compact, fanless designs allow them to fit into small spaces on board while maintaining their resilience.

Fanless industrial PCs are employed by companies across various industries to ensure stable, reliable performance in harsh environments. Here are a few examples:

BV-Series Fanless Industrial PC

Known for its durable build, the BV-Series fanless industrial PC from BVS IPC is designed specifically for high-vibration environments. Its fanless architecture and SSD integration make it a top choice for manufacturing facilities, where stable performance is essential. The model’s rugged casing provides additional protection against external mechanical stresses, making it a valuable asset for industries relying on continuous uptime.

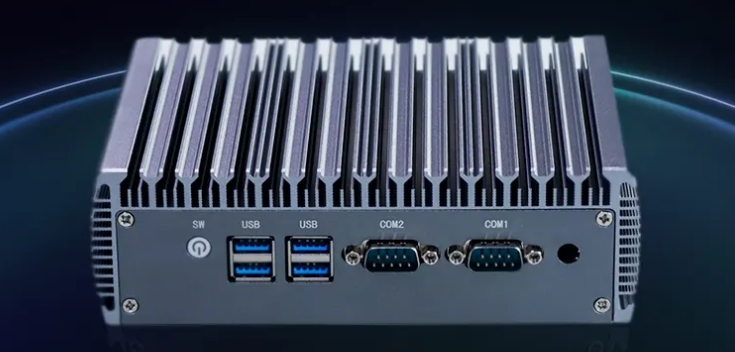

BSI Fanless Micro PC

This fanless micro PC model is tailored for transport and logistics sectors, where it can handle tasks like GPS monitoring and real-time data logging. Built with a shock-absorbing casing and vibration-resistant components, the BSI fanless micro PC offers reliable performance in high-vibration settings, ensuring smooth operation in demanding conditions.

BZ Series Fanless Embedded PC

The BZ Series fanless embedded PC features a compact design and vibration-resistant features, making it ideal for applications in mining and construction. This model can be easily installed on heavy-duty equipment and provides continuous performance without the risk of overheating or hardware failure due to vibrations.

For high-vibration industrial environments, fanless industrial PCs offer unparalleled durability and reliability. By using SSDs, shock-resistant mounts, and rugged casings, these PCs can withstand mechanical stress that would compromise standard computers. Their fanless design also means fewer parts are subject to wear and failure, which reduces maintenance needs and extends the lifespan of the device. With products like the BV-Series, BSI Fanless Micro PC, and BZ Series Fanless Embedded PC, companies have a range of options to choose from, each designed to address specific needs in vibration-prone settings. For industries where reliability and resilience are paramount, fanless industrial PCs provide a solid, long-term solution.

Click to confirm

Cancel