In the world of controlled environments, cleanrooms stand as bastions of purity, where even the smallest particle can disrupt critical processes. These specialized spaces are essential in various industries, from pharmaceutical manufacturing to semiconductor production. As technology advances, the need for reliable computing solutions in these pristine environments has grown. Enter the fanless industrial PC, a game-changing device that addresses the unique challenges of cleanroom computing.

Cleanrooms face several hurdles when it comes to integrating technology:

1. Particle contamination: Traditional computers with fans can circulate dust and other particles, compromising the sterile environment.

2. Temperature regulation: Electronic equipment generates heat, which can affect sensitive processes and materials.

3. Equipment durability: Cleanroom devices must withstand frequent cleaning and sterilization procedures.

These challenges emphasize the need for specialized computing solutions that can work efficiently while maintaining the cleanroom's integrity.

Fanless industrial computers offer numerous advantages that make them ideal for cleanroom applications:

1. Reduced Particle Emissions: By eliminating fans, these industrial personal computers significantly decrease the risk of particle dispersion, maintaining the cleanroom's purity.

2. Improved Reliability: Fanless industrial PCs have fewer moving parts, reducing the likelihood of mechanical failures and extending the device's lifespan.

3. Enhanced Temperature Management: These industrial mini PCs use passive cooling techniques, such as heat sinks and specially designed casings, to dissipate heat effectively without the need for fans.

4. Simpler Maintenance: The smooth, sealed surfaces of fanless industrial box PCs are easier to clean and sterilize, aligning with stringent cleanroom protocols.

5. Space-Efficient Design: Many fanless industrial computers come in compact form factors, allowing for flexible installation in space-constrained cleanroom environments.

To illustrate the key differences between traditional PCs and fanless industrial PCs, consider the following comparison:

|

Feature |

Traditional PC |

Fanless Industrial PC |

|

Cooling Method |

Fan-based |

Passive (heat sinks, etc.) |

|

Particle Emission |

High |

Minimal |

|

Reliability |

Moderate |

High |

|

Maintenance |

Complex |

Simple |

|

Cleanroom Compatibility |

Low |

High |

|

Form Factor |

Various |

Compact, industrial mini PC |

Fanless industrial computers find use in various cleanroom settings:

1. Pharmaceutical Manufacturing: These advanced industrial computers monitor and control drug production processes, ensuring consistency and quality.

2. Semiconductor Production: Fanless industrial PCs manage sensitive equipment in chip fabrication, where even microscopic particles can cause defects.

3. Medical Device Assembly: Industrial fanless PCs support precision assembly of medical devices, maintaining sterility throughout the process.

4. Food Processing: In clean food production areas, these industrial box PCs help control equipment while minimizing contamination risks.

When selecting a fanless industrial computer for cleanroom use, consider these factors:

1. Sealed Enclosure: Look for IP-rated casings that protect against dust and moisture ingress.

2. Passive Cooling Efficiency: Evaluate the heat dissipation capabilities to ensure reliable operation in your specific environment.

3. Cleanroom Certification: Check if the industrial PC meets relevant cleanroom standards (e.g., ISO 14644).

4. Performance Specs: Choose a model with appropriate processing power and memory for your applications.

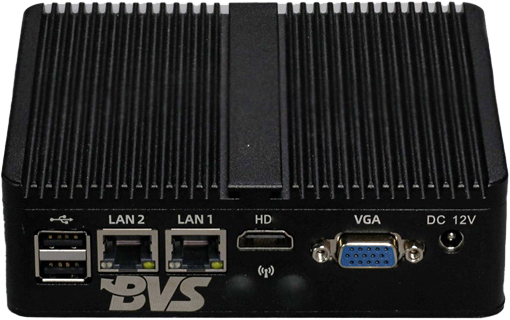

5. Connectivity Options: Ensure the device has the necessary ports and interfaces for your cleanroom equipment.

The field of cleanroom computing continues to evolve:

1. Advanced Cooling Technologies: New materials and designs are enhancing passive cooling capabilities, allowing for more powerful fanless industrial PCs.

2. IoT Integration: Industrial personal computers are increasingly incorporating IoT features, enabling better data collection and analysis in cleanroom environments.

3. AI-Powered Systems: Fanless industrial computers with AI capabilities are emerging, offering smarter process control and predictive maintenance in cleanrooms.

These advancements promise to further enhance the capabilities of fanless industrial PCs in cleanroom applications, making them even more valuable tools for maintaining sterile environments while supporting critical processes.

At BVS, we specialize in designing fanless industrial PCs that meet the stringent demands of cleanroom environments across various industries. Our advanced industrial mini PCs and box PCs are engineered with passive cooling technology to ensure reliable performance without compromising cleanroom integrity. Whether for pharmaceutical cleanrooms or semiconductor manufacturing, we offer tailored solutions through close collaboration with cleanroom operators. This approach has made us a trusted partner in cleanroom technology, and we remain dedicated to delivering innovative products that uphold the highest standards of cleanliness and productivity.

Fanless industrial PCs rely on passive cooling techniques, using specially designed heat sinks and sealed enclosures to dissipate heat effectively. This design ensures the industrial PC operates efficiently without generating particles from moving parts, making it ideal for sensitive cleanroom environments.

Yes, fanless industrial PCs are designed to handle demanding tasks, even in cleanroom environments. With advanced processors, efficient heat dissipation, and durable construction, these devices can manage complex operations, from controlling sensitive equipment to monitoring production processes, without compromising cleanroom integrity.

Click to confirm

Cancel