Fanless industrial PCs are specialized computing devices designed to operate without the need for cooling fans. Unlike traditional industrial PCs that rely on fans to dissipate heat, fanless industrial computers utilize passive cooling methods such as heat sinks, heat pipes, and advanced chassis designs to manage thermal output. These industrial mini PCs are built to withstand harsh environments and demanding industrial applications, providing reliable performance without the noise and mechanical failure risks associated with fan-based systems.

Key characteristics that differentiate fanless industrial PCs from traditional industrial personal computers include:

In industrial settings, energy efficiency is crucial for reducing operational costs and minimizing environmental impact. Efficient energy use directly translates to lower electricity bills and contributes to sustainability efforts by reducing the carbon footprint. Thermal management is equally important as it ensures the reliability and longevity of electronic components. Effective thermal management prevents overheating, which can lead to system failures, data loss, and costly downtime. By maintaining optimal operating temperatures, fanless industrial PCs enhance the performance and durability of industrial box PCs, making them suitable for continuous operation in challenging environments.

One of the core strategies for achieving energy efficiency in fanless industrial PCs is the use of low-power components. These components are specifically designed to consume less energy while maintaining high performance.

Key elements include:

In addition to using low-power components, fanless industrial PCs employ optimized power management techniques to enhance energy efficiency further. These include:

Power-Saving Modes and Technologies: Many industrial mini PCs are equipped with power-saving modes that automatically reduce power consumption during periods of low activity. Technologies such as dynamic voltage and frequency scaling (DVFS) adjust the power usage of the CPU and GPU based on the current workload, ensuring that only the necessary amount of power is used at any given time.

Efficient Power Supply Units (PSUs): The efficiency of the power supply unit is critical for overall energy efficiency. High-efficiency PSUs convert more of the input power into usable output power, reducing waste and heat generation. This not only lowers energy consumption but also contributes to the effective thermal management of the system.

Implementing energy-efficient design principles in fanless industrial PCs offers several significant benefits:

Effective thermal management in fanless industrial PCs relies heavily on advanced heat dissipation methods to maintain optimal operating temperatures without the need for active cooling systems. Key methods include:

The choice of materials and the design of the chassis play a crucial role in the thermal management of fanless industrial PCs:

Thermal Interface Materials (TIMs): TIMs are used to enhance the thermal connection between heat-generating components (such as CPUs and GPUs) and heat sinks. High-quality TIMs, like thermal pastes or pads, reduce thermal resistance and improve heat transfer efficiency.

Chassis Design for Optimal Heat Dispersion: The chassis of fanless industrial PCs is often designed with integrated heat dissipation features. This includes the use of finned structures and large surface areas to facilitate effective heat dispersion. Some designs incorporate the entire chassis as a heat sink, leveraging materials with high thermal conductivity to spread and dissipate heat evenly.

Modern fanless industrial PCs incorporate intelligent technologies to optimize thermal management dynamically:

Intelligent Thermal Control Algorithms: These algorithms manage the thermal performance of the industrial box PC by adjusting power and workload distribution based on real-time thermal data. This ensures components operate within safe temperature ranges, enhancing reliability and performance.

Temperature Sensors and Real-Time Monitoring: Embedded temperature sensors provide continuous monitoring of key components and system temperatures. Real-time data from these sensors allow the system to make immediate adjustments to prevent overheating and ensure optimal thermal conditions.

One of the most notable advantages of fanless industrial PCs is their ability to operate silently:

Fanless industrial PCs offer enhanced reliability and durability due to their robust design:

The design of fanless industrial PCs contributes to lower maintenance needs and increased productivity:

Lower Maintenance Requirements: Without fans, there is no need for regular cleaning or replacement of these components. This reduces the overall maintenance burden and associated costs.

Increased Uptime and Productivity: The reliability and low maintenance of fanless PCs translate to less downtime. As a result, operations can continue smoothly without frequent interruptions for repairs or maintenance, leading to improved productivity and efficiency in industrial settings.

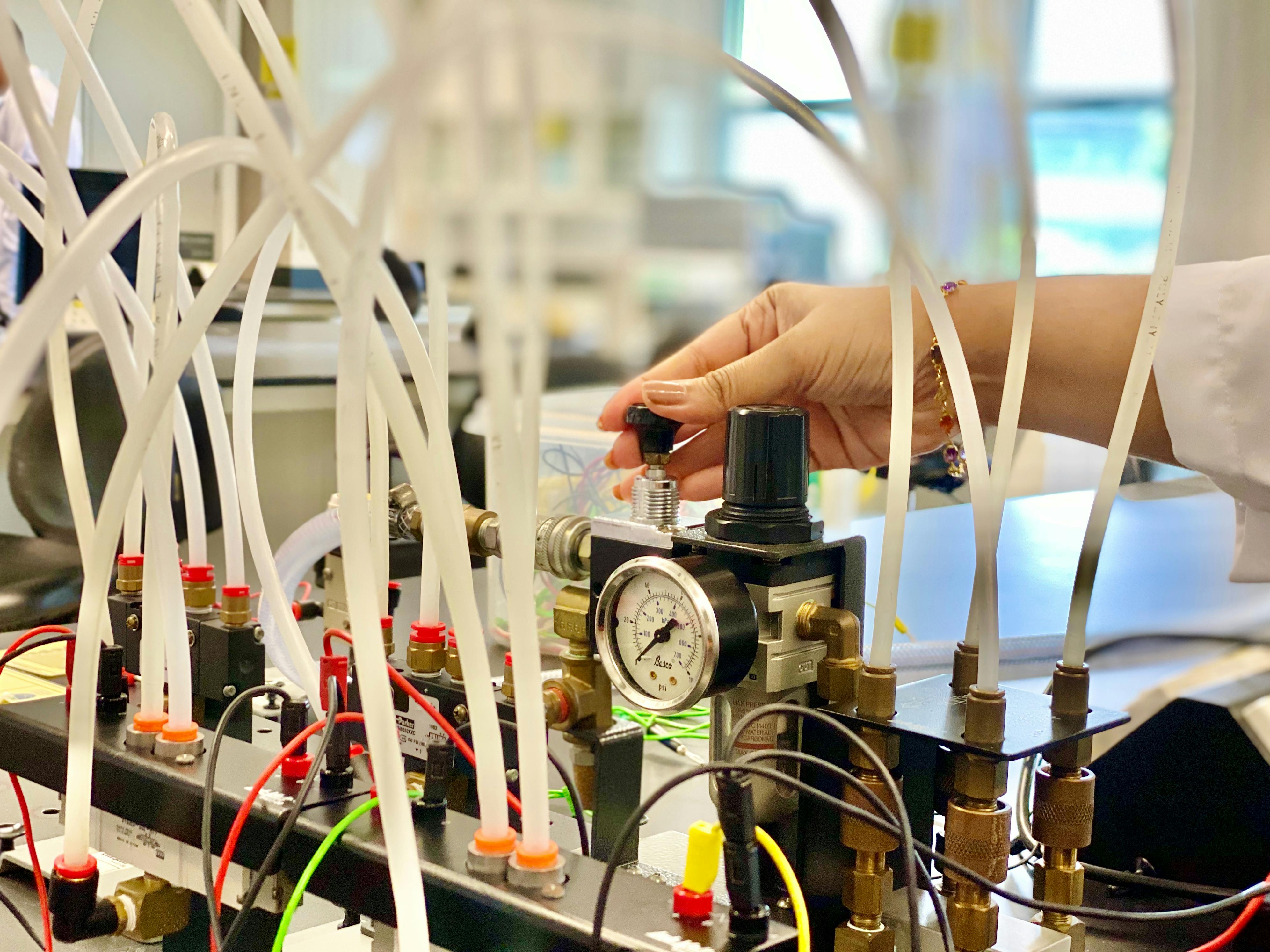

Fanless industrial PCs are extensively used in factory automation and control systems. In these environments, they serve as the backbone for various automated processes, controlling machinery, monitoring production lines, and managing data acquisition systems.

Fanless PCs are ideal for outdoor kiosks and rugged applications, where they are exposed to extreme temperatures, humidity, and dust.

Fanless industrial PCs are frequently used in medical devices and healthcare systems, including diagnostic equipment, patient monitoring systems, and surgical instruments.

In summary, fanless industrial PCs demonstrate significant advantages across various real-world applications, including industrial automation, outdoor and harsh environments, and medical and healthcare equipment. Their robust design, energy efficiency, and reliable performance

Click to confirm

Cancel