Downtime is one of the most significant, yet often underestimated, threats to a business's profitability. This is particularly true in industries where uninterrupted operation is key, like manufacturing and logistics. Even a brief halt can result in thousands, if not millions, of dollars in losses. Beyond the immediate financial impact, there are hidden costs—damage to client trust, lost opportunities, and a weakened competitive position in the market.

As businesses evolve and operations grow more complex, outdated technology, such as older embedded computers, can amplify the risk of downtime. Industries that fail to modernize face mounting technical challenges, while those that invest in industrial embedded computers experience fewer disruptions and greater long-term stability.

Outdated systems are like ticking time bombs. Industrial environments today demand far more from their systems than in previous decades. Older embedded PCs and legacy industrial computers may still work, but they can’t keep up with the high-speed demands of modern operations. The result? More frequent breakdowns, slower response times, and ballooning maintenance costs. Over time, businesses that continue relying on obsolete technology fall into a cycle of paying to fix problems instead of investing in solutions that could prevent them.

By clinging to outdated systems, businesses accrue technical debt—the cost of maintaining old, inefficient equipment. Rather than continually patching up outdated hardware, it’s more cost-effective to invest in new industrial embedded computers, which provide the reliability and efficiency required to stay competitive.

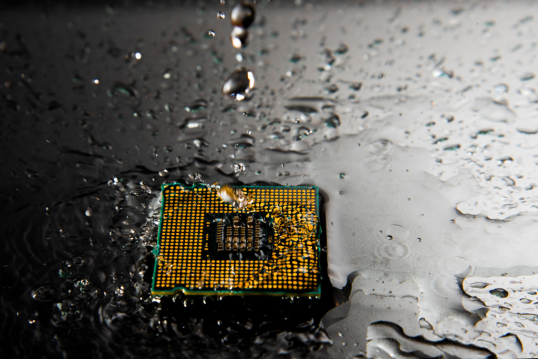

So, what exactly is an industrial embedded computer, and why is it vital for modern industries? These devices are specifically designed to handle extreme conditions while maintaining high performance. Unlike consumer-grade systems, industrial embedded PCs are built to endure rugged environments. Whether they're exposed to vibrations, extreme temperatures, or dusty conditions, these computers are engineered to keep running smoothly.

|

Feature |

Consumer PC |

Industrial Embedded PC |

|

Durability |

Low |

High |

|

Operational Temperature Range |

Narrow |

Wide |

|

Lifespan |

Short |

Long |

|

Downtime Risk |

High |

Low |

For businesses operating in tough environments or those requiring non-stop operation, upgrading to an industrial embedded PC is essential. These computers ensure greater uptime, which translates to smoother operations and fewer disruptions.

Industrial embedded computers excel at minimizing downtime because they are designed for stability and resilience. Unlike standard embedded computers, they are built to withstand harsh environmental factors such as extreme temperatures, dust, and continuous vibrations—elements that can easily cause consumer-grade hardware to fail.

The ability to run around the clock is one of the most significant advantages of industrial embedded PCs. They are designed for constant, reliable operation, which means businesses experience fewer interruptions and don't have to worry about frequent hardware failures. These systems are particularly well-suited for real-time data processing, allowing potential issues to be identified and addressed before they lead to costly shutdowns.

Reducing downtime leads to substantial cost savings. Investing in industrial embedded computers pays dividends by decreasing disruptions, cutting maintenance expenses, and extending equipment longevity. Let’s take a closer look at the financial benefits:

|

Financial Impact |

Traditional Systems |

Industrial Embedded Computer |

|

Downtime Frequency |

High |

Low |

|

Maintenance Costs |

High |

Low |

|

Equipment Replacement Costs |

Frequent |

Infrequent |

|

Operational Efficiency |

Reduced |

Consistent |

The return on investment (ROI) from upgrading to industrial embedded computers is clear. With fewer breakdowns, less downtime, and reduced maintenance costs, businesses can hit their production goals more reliably and maintain a steady cash flow. Over time, the savings from increased operational efficiency and reduced hardware failure far outweigh the initial costs of these systems.

In addition to reducing downtime, industrial embedded computers play a critical role in enhancing overall operational efficiency. These systems power automation technologies, enabling businesses to streamline processes, reduce human error, and optimize productivity. Embedded box PCs, for instance, can control complex machinery on factory floors, allowing companies to automate routine tasks and improve throughput.

Moreover, many industrial embedded computers feature remote monitoring capabilities, giving businesses the power to oversee their systems in real time. This allows for predictive maintenance, where potential issues are identified and fixed before they result in downtime. With this proactive approach, businesses can keep operations running smoothly while minimizing the risk of costly disruptions.

Industrial embedded computers are built not just for today’s needs but for tomorrow’s challenges. Technology is advancing rapidly, and businesses must be prepared to evolve. Embedded industrial PCs can easily integrate with new technologies, making them adaptable to growing data loads and more complex processes without frequent upgrades.

Longevity is another key benefit. Unlike consumer-grade systems, which often need to be replaced every few years, industrial embedded PCs can last for a decade or more. This durability not only reduces replacement costs but also keeps operations running smoothly for longer periods, minimizing downtime and ensuring long-term profitability.

Selecting the right industrial embedded computer depends on the specific needs of your business. Whether you’re in manufacturing, energy, transportation, or healthcare, your requirements will vary. For example, a manufacturing plant may need an embedded box PC that can withstand constant vibrations, while a healthcare facility might require an embedded industrial PC that excels in real-time data processing for medical devices.

It’s essential to evaluate the operational environment, processing power, and security needs when choosing your industrial embedded PC. By selecting the right system, you can prevent interruptions, enhance operational efficiency, and maintain your competitive edge.

When it comes to industrial embedded computers, selecting the right manufacturer is just as crucial as choosing the right product. At BVS, we specialize in providing durable, high-performance embedded computers designed for the most demanding industrial environments. As a leading industrial computer manufacturer, our products help businesses reduce downtime, improve operational reliability, and achieve long-term success.

Click to confirm

Cancel