In today’s rapidly advancing manufacturing industry, the need for efficient, reliable, and flexible computing systems is more critical than ever. Enter the industrial PC (IPC) — a rugged, high-performance computer designed specifically for harsh environments. IPCs have become a backbone in industries that require continuous operation in extreme conditions, offering enhanced stability, longevity, and functionality.

Manufacturing is one such industry where the industrial PC plays a pivotal role. With the rise of automation, robotics, and intelligent manufacturing processes, industrial PCs are helping companies optimize productivity, streamline operations, and maintain operational efficiency. In this blog, we will explore the various applications of industrial PCs in the manufacturing industry, highlighting their capabilities and how they are revolutionizing factory operations.

The manufacturing sector is one of the most demanding environments for computing hardware. Industrial PCs are built to withstand extreme conditions such as temperature fluctuations, dust, moisture, and vibrations, making them ideal for factory floors, warehouses, and other industrial settings. Let’s take a deeper look into the applications and benefits of industrial PCs in manufacturing:

1. Automation Systems

The integration of automation systems in manufacturing processes is one of the most notable advancements in recent years. Industrial embedded computers are the heart of these systems, controlling everything from assembly lines to robotic arms. The reliability and real-time processing power of IPCs allow for seamless coordination between machines and systems, significantly enhancing productivity.

2. Robotics and Machine Control

Industrial robots, which are commonly used in repetitive tasks such as welding, painting, or assembly, rely on industrial mini PCs to control their movements and processes. These robots interact with sensors, actuators, and other devices to execute precise tasks. The computational power of industrial PCs ensures that robots can operate without interruption, optimizing production efficiency.

3. Monitoring and Data Collection

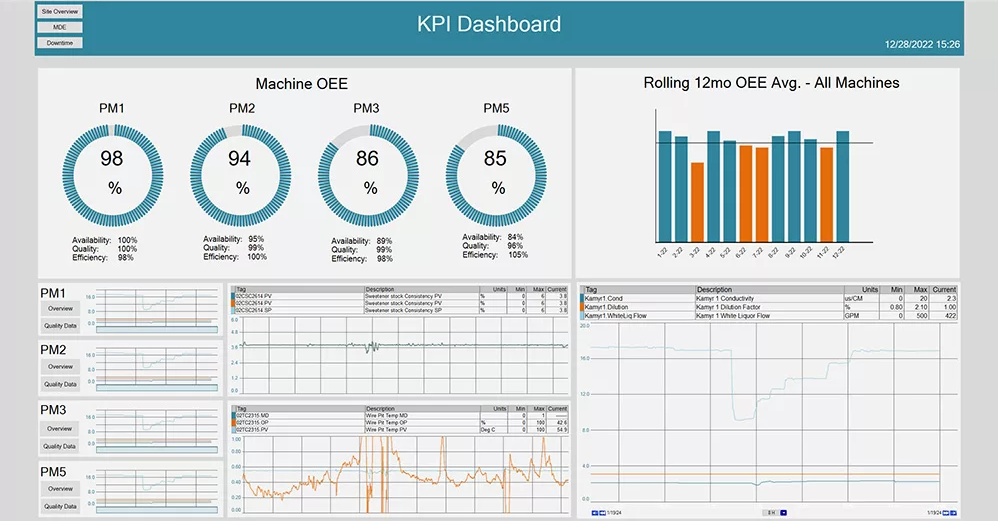

In modern manufacturing, continuous monitoring of machines and processes is essential for detecting faults, tracking performance, and ensuring quality control. Industrial PCs enable the collection of data from various machines in real-time. They help monitor temperature, pressure, speed, and other critical parameters to ensure that everything operates within the desired specifications. This data is essential for predictive maintenance, reducing downtime, and increasing the longevity of expensive machinery.

4. Process Visualization

In industries like automotive or food production, workers need to monitor a large amount of data across multiple systems. An industrial computer equipped with a high-definition touch interface can visualize these systems, displaying crucial information about each process in real-time. This level of visibility improves decision-making and helps workers identify issues before they lead to costly downtime.

5. Energy Efficiency and Sustainability

With energy costs rising and environmental concerns becoming more pressing, manufacturers are turning to industrial PCs for solutions that can help optimize energy usage. Through intelligent control systems powered by industrial embedded computers, companies can minimize energy consumption, streamline processes, and reduce their carbon footprint. IPCs can also track energy usage data, helping manufacturers comply with sustainability standards and regulations.

1. Durability and Longevity

One of the standout features of industrial PCs is their robustness. Unlike traditional consumer-grade computers, IPCs are designed to operate in harsh environments, withstanding extreme temperatures, vibrations, and humidity. This durability ensures that the system remains functional in demanding conditions for longer periods, making them a cost-effective choice in the long run.

2. Customization and Scalability

Manufacturers can customize industrial embedded computers to meet specific needs. Whether it’s adjusting the hardware for a unique application or scaling up for larger operations, IPCs offer unparalleled flexibility. From a small industrial mini PC that controls a single process to a large-scale system that integrates with an entire factory, IPCs can be tailored to fit a wide range of operational requirements.

3. Real-Time Performance

The ability to process data in real-time is crucial in manufacturing, where split-second decisions can impact productivity. Industrial PCs offer powerful processors and memory, ensuring that data is processed instantly and without delays. This is vital for applications like robotics, monitoring, and controlling automated systems.

|

Type of Industrial PC |

Key Features |

Applications |

|

Compact, rugged, low power consumption |

Automation control, data collection, and monitoring |

|

|

Industrial Mini PC |

Small form factor, high performance, cost-effective |

Robotics, process visualization, machine control |

|

Industrial Computer |

High processing power, customizable |

Large-scale data processing, factory management systems |

|

Integrated touch screens, multi-functionality |

Process visualization, HMI (Human-Machine Interface) |

The industrial PC has revolutionized manufacturing by providing a stable, reliable, and scalable computing solution for modern automation systems. From improving process automation to enhancing real-time data monitoring, industrial embedded computers and industrial mini PCs are driving efficiency and productivity in factories across the globe. As the demand for smarter, more connected manufacturing systems grows, the role of IPCs will only become more prominent.

As industrial computer manufacturers continue to innovate, we can expect further advancements in the capabilities of IPCs, including enhanced AI integration, more powerful processors, and even more energy-efficient solutions. The future of manufacturing lies in the hands of these sophisticated machines that offer unparalleled reliability and versatility in every industry they serve.

Looking for high-performance industrial PCs for your manufacturing or automation needs? Explore our range of Embedded Industrial PC products, built to endure tough environments and deliver exceptional performance. This holiday season, enjoy our exclusive Christmas discount and make the most of unbeatable deals on IPC purchases. Don’t miss out—visit BVS product page here to get your industrial PC today and make this Christmas season more productive than ever!

If you want to know more about industrual pc, please click the follows:

① Top 10 Mini PCs 2024: Best Mini PC Rankings and Reviews

② Exploring the Advantages of Fanless Computers for Modern Applications

Click to confirm

Cancel